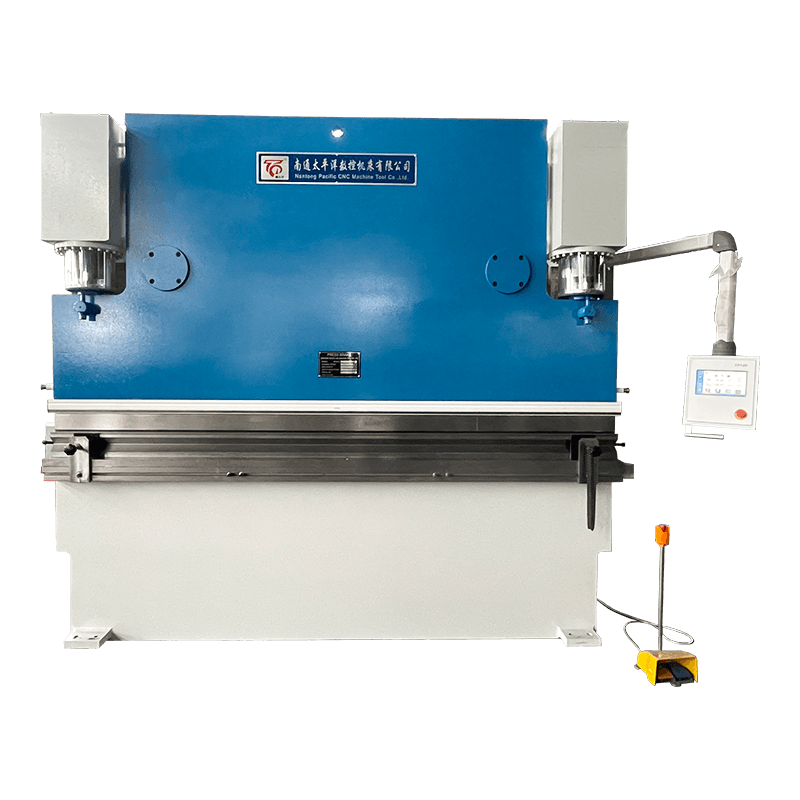

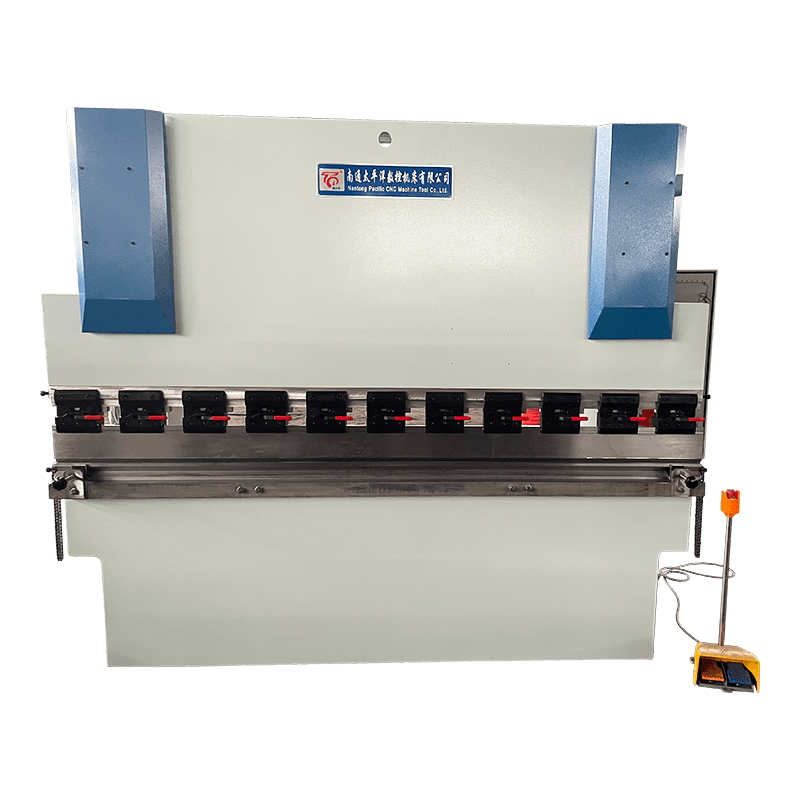

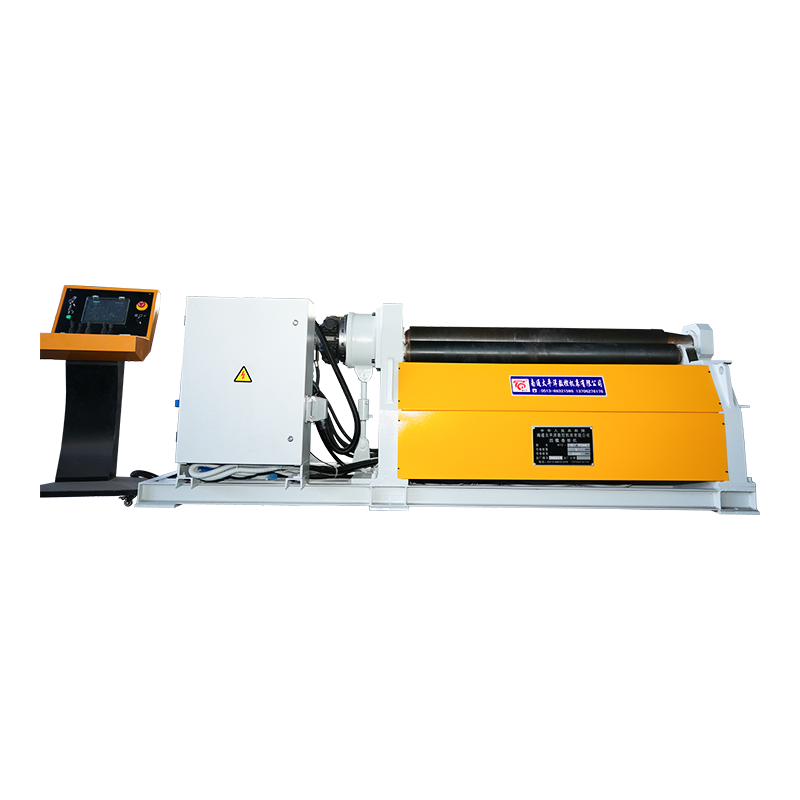

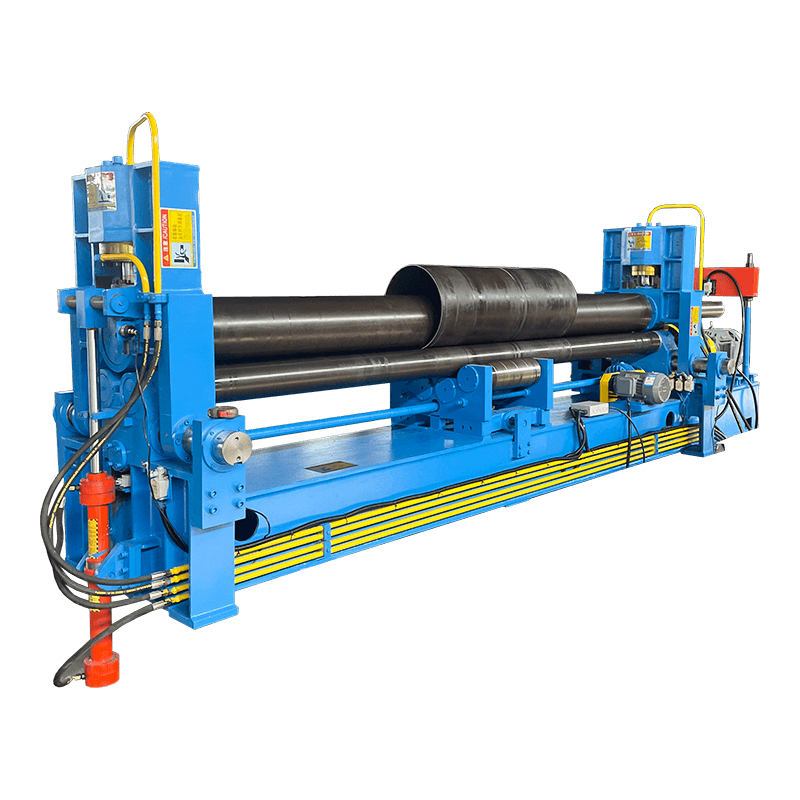

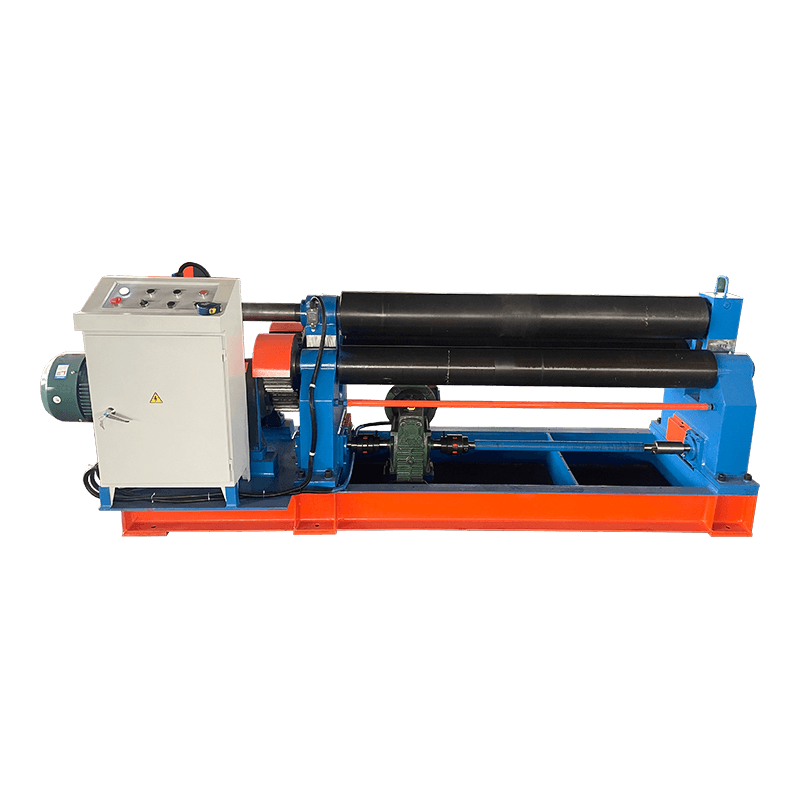

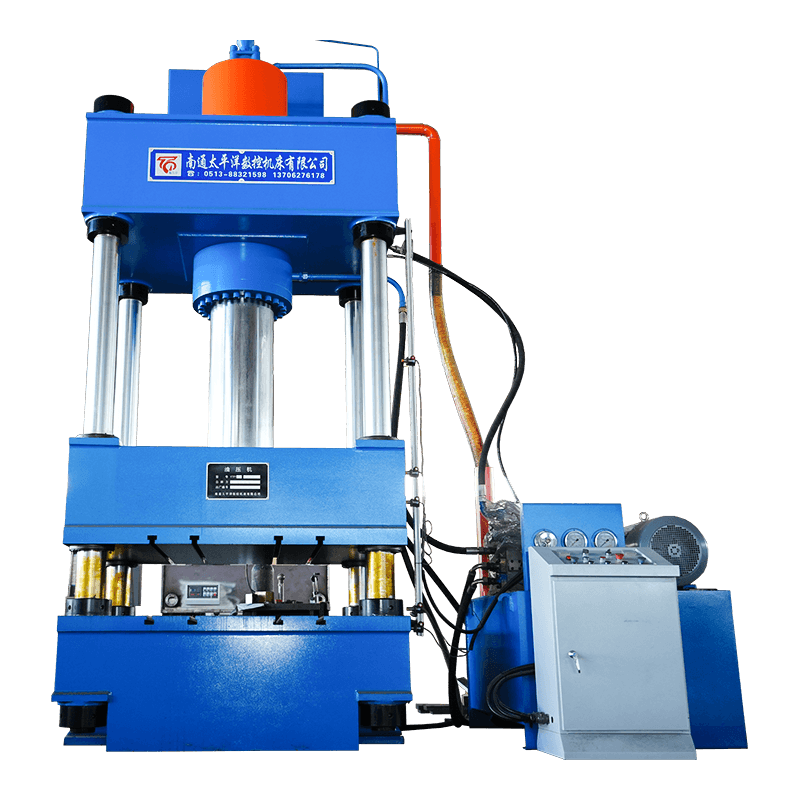

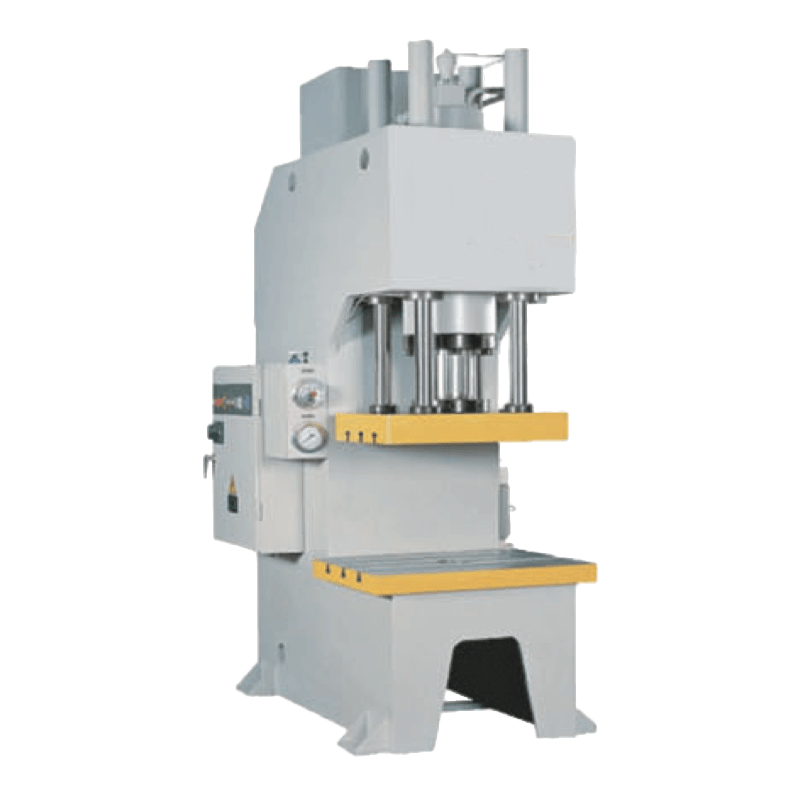

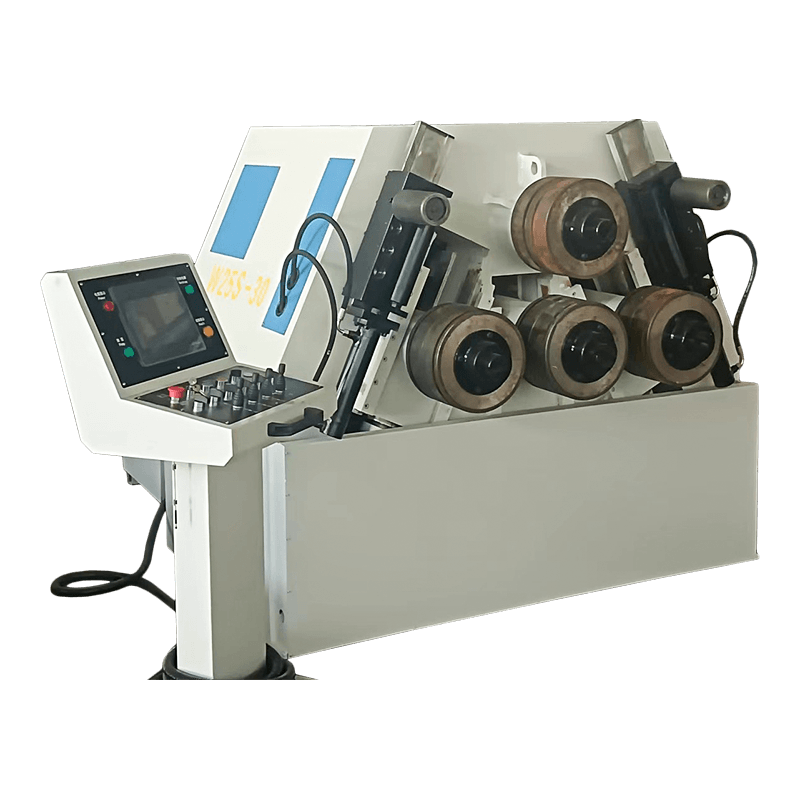

Nantong Pacific Cnc Machina Tool Co., Ltd is a key enterprise of national machinery industry, located in Haian Economic and Technological Development Zone, where the environment is beautiful and the traffic is convenient, which facilitates the rapid establishment of communication between enterprises and customers. The enterprise is fully equipped, specializing in the production of shearing machine, bending machine, rolling machine, hydraulic press, punching machine and other productus, widely used in: light industry, aviation, shipbuilding, metallurgy, instrumentation, electrical appliances, stainless steel products, construction and decoration industry. Our products sell well both at home and abroad.

Ut professional China WC67K Series Torsionem axis Synchronous Cnc Hydraulic sheet metallum tendentes machina Manufacturers and WC67K Series Torsionem axis Synchronous Cnc Hydraulic sheet metallum tendentes machina Factory, De turba autem habet facultatem ad consilium, develop et fabricantium vexillum series products et non-vexillum apparatu. Products vendere bene per regionem, magna numerus exportantur ad meridiem Asia, Europa, in Civitatibus Foederatis Americae et Medio Oriente. In comitatu tegit aream plus quam 20,000 quadratum metris, cum coetus et fabrum et technicae cum dives professional scientia, productio et testis apparatu est completum. Per annos, est committed ad investigationis et innovation of fudentes machine instrumenta, in productum venditio et post-venditionesque servitium non parcens nullum conatus, in Beijing, Tianjin, Shandhai, Sale, Sale, Sale: Nostra optima in occursum necessitates domesticis et aliena customers.

In hodie mundi plena spes et occasiones, Pacific apparatus instrumenta et customers ire manu in manu ad commune development.